Products

ONE

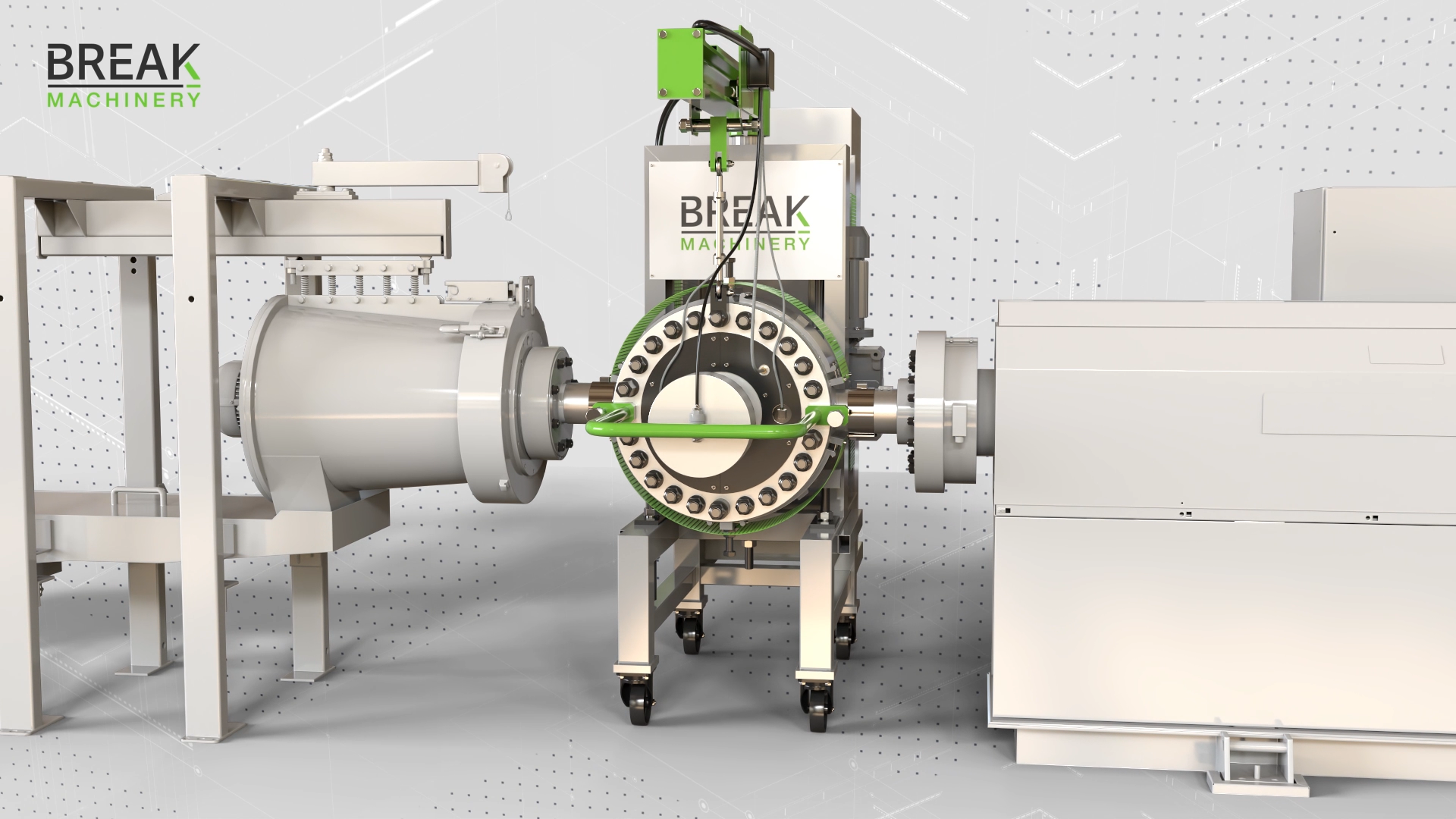

Automatic self-cleaning filtering system

Reliability

Efficiency

Ease of management

Efficiency

Ease of management

ONE is suitable for the production of: Recycling granules, polymerisation granules, masterbatch and compound granules, adhesives (Hot Melt).

ONE has been designed to the highest quality standards and has passed the most stringent production tests on various types of equipment, ensuring excellent filtering performance.

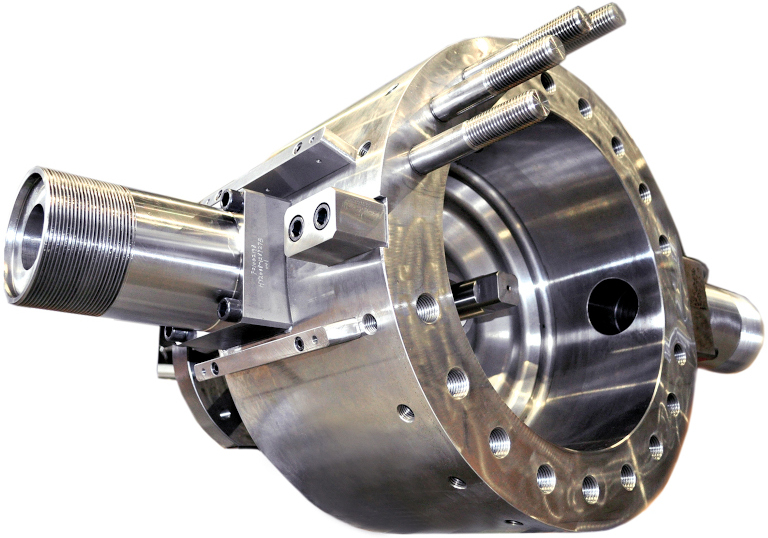

The careful study of mechanisms, materials and the filtration chamber is the engineering element that has enabled us to achieve our standards.

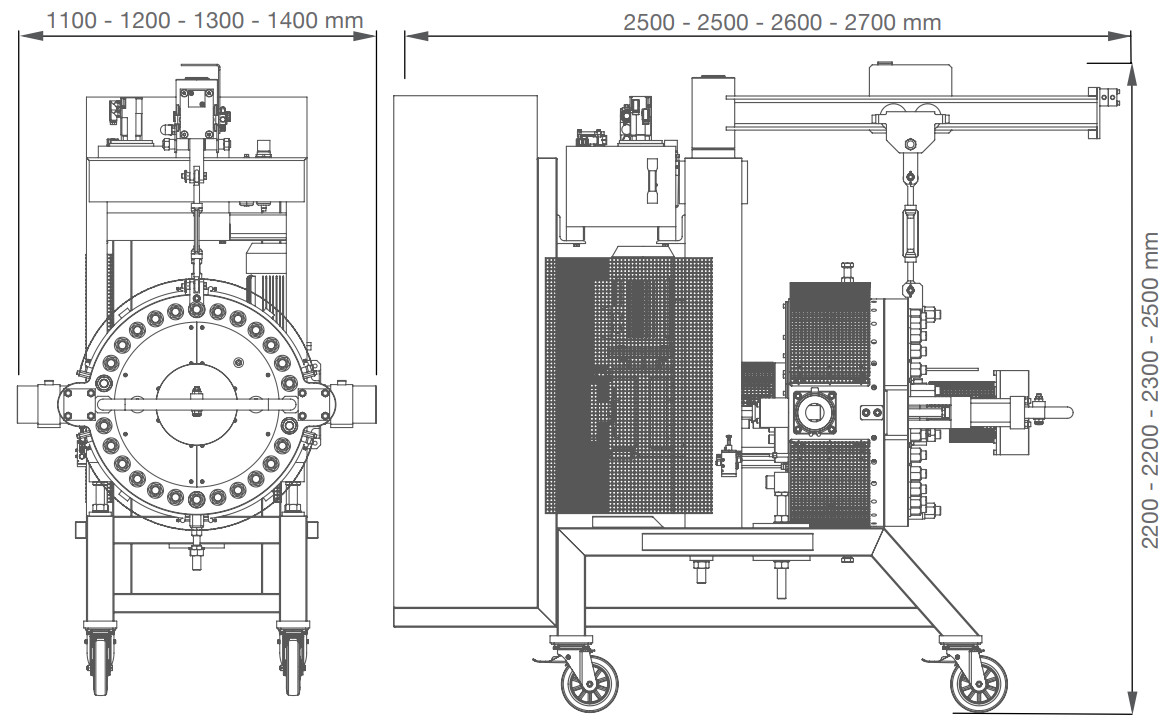

| L (mm) | H (mm) | W (mm) | |

| ONE 400 | 2500 | 2200 | 1100 |

| ONE 500 | 2500 | 2200 | 1200 |

| ONE 600 | 2600 | 2300 | 1300 |

| ONE 700 | 2700 | 2500 | 1400 |

Break Machinery ONE video

Automatic continuous self-cleaning filter for plastic compound video

Main Components

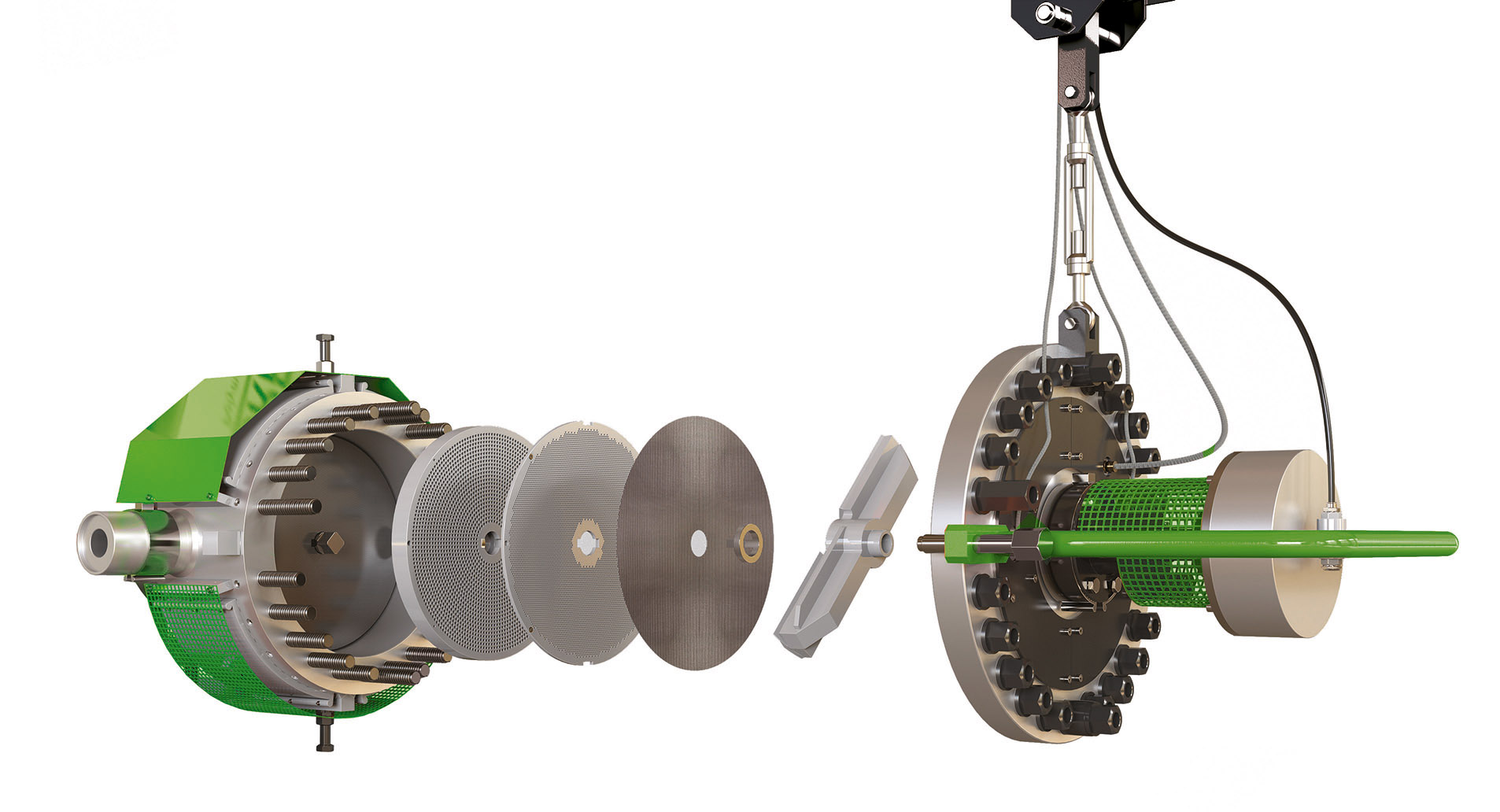

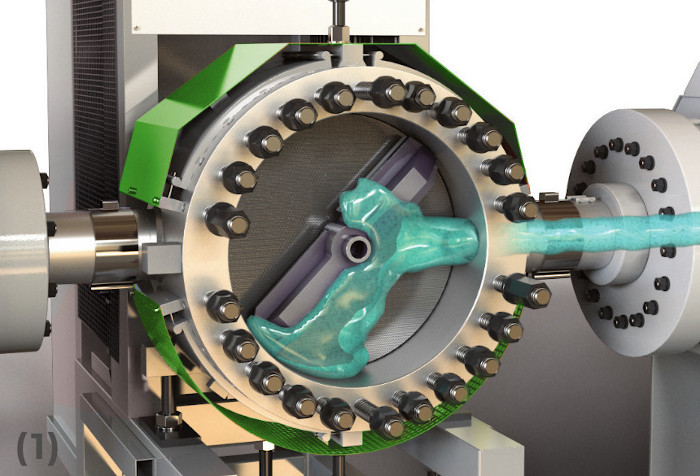

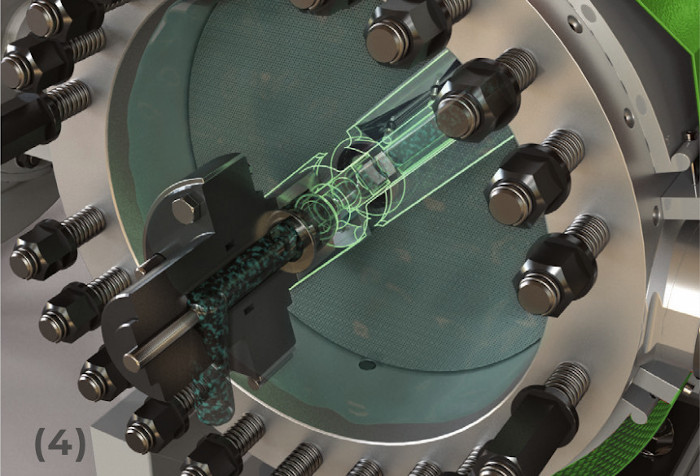

Steel breaker and screen

The scraping operation mode uses a thick steel breaker coupled with a thinner breaker (Optional), and an interchangeable steel screen (punched or laser micro-perforated) for filtrations from 60 to 2000 microns.

Touch screen displays

ONE can be customized with touch screen displays, agreeing with the customer the graphic layout and the desired reading parameters.

Spacer and scraper

A spacer allows the scraper blades to work at the right distance from the screen so as not to damage it.

Interconnected

ONE can be connected with the company’s 4.0 communication network. The machine is prepared for assembly according to the Customer’s needs, with inlet and outlet flanges.

Advantages

Increased production

Increased production thanks to the automatic cleaning of the filter changer and the absence of traditional interruptions due to operator filter changes.

Reliability

The construction process, from design to the choice of materials and assembly in our factories guarantees the highest quality product in terms of performance and durability.

Simplicity of operation

The simplicity of its construction allows ordinary and extraordinary maintenance directly at the customer’s premises, reducing downtime to a minimum.

Productivity

The continuous filtering system maximises line productivity, compared to traditional cassette systems.

Savings

The efficiency of the cleaning system in continuous mode results in longer utilisation of the laser filter, with a consequent reduction in the purchase of consumables.

Efficiency

The ONE automatic continuous flow filter optimises the filtration of impurities without compromising line productivity by reducing production waste.

Operating Principle

The extruder pushes the contaminated plastic material into the ONE filter changer.

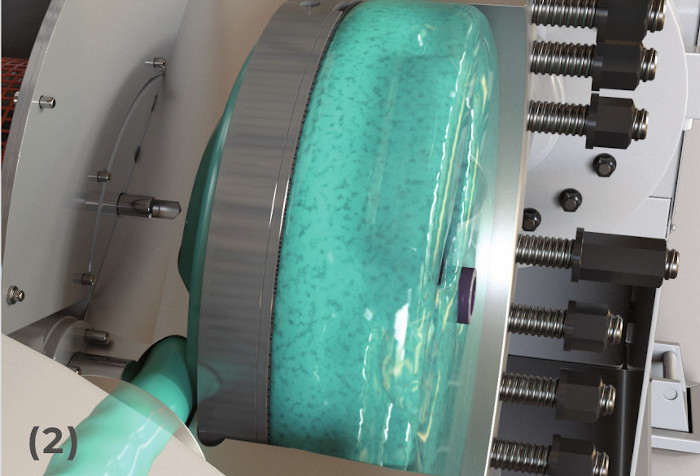

A punched or laser-drilled steel filter, with the filter capacity chosen by the customer, removes impurities from the plastic material.

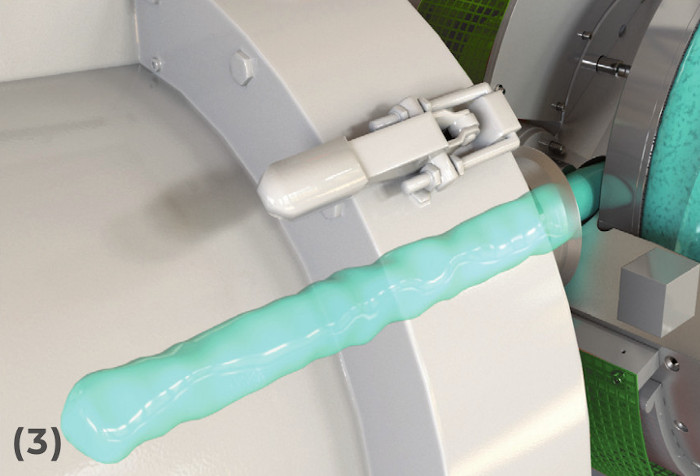

The filtered and purified material leaves the ONE filter changer for further processing.

All impurities are collected inside the scraper and automatically discharged through the discharge valve.

Technical characteristics

Filtering surfaces

The filter surfaces ensure that pressure variations are handled with precision to avoid altering the flow of plastic material.

Stability

Process stability is ensured by the automatic control of the filter mechanisms.

Waste management

Waste material is easily handled, with automatic shearing of the material and depositing it on the ground or on a special emptying container.

Simplicity of use

The simplicity and solidity of construction make the system optimal for the safety of operators during routine maintenance operations.

| AUTOMATIC CONTINUOUS SELF-CLEANING FILTER SCRAPING/SCRAPING BACK FLUSHING |

||||

|---|---|---|---|---|

| ONE 400 | ONE 500 | ONE 600 | ONE 700 | |

| Filter diameter (mm) | Ø 400 | Ø 500 | Ø 600 | Ø 700 |

| Surface (cm2) | 1206 | 1916 | 2783 | 3807 |

| Laser filter | micron: from 60 to 300 mesh: from 230 to 50 |

|||

| Punched filter | micron: from 400 to 2000 mesh: from 40 to 10 |

|||

| Metallic mesh filter | controflusso: micron: from 60 to 2000 mesh: from 230 to 10 |

|||

| Filtered materials | PP / LDPE /LLDPE / HDPE PS / EPS / XPS / ABS / TPU |

|||

REQUEST INFORMATION

Our sales and technical department are at your disposal for advice and to give you all the necessary information on the filters that best suit your needs.