insights

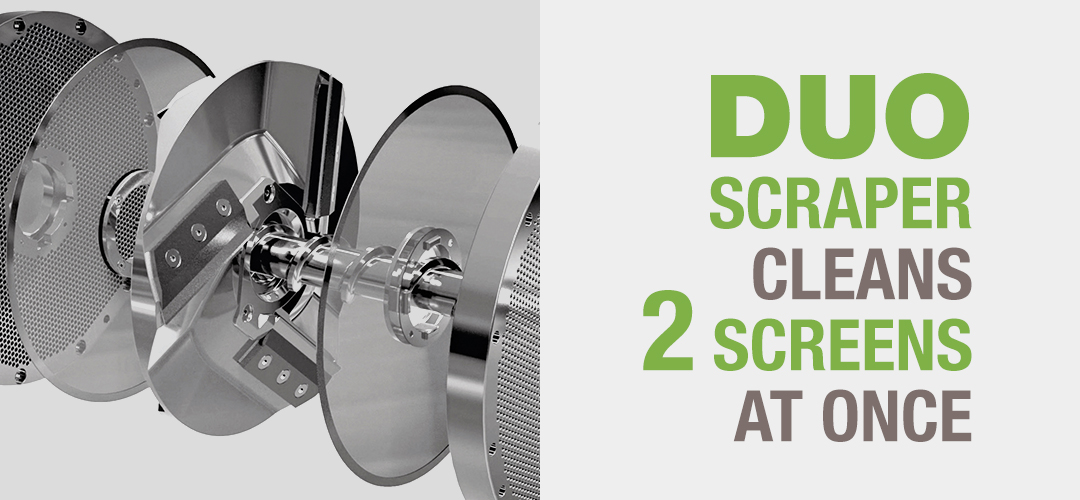

DUO scraper: cleans 2 screens at once

DUO is equipped with a 6-blade scraper designed for improved filtering efficiency, even at low rotation speeds. Placed between 2 screens, the DUO scraper provides continuous cleaning of both screen surfaces at once, while also preventing the contamination from re-entering the melt.

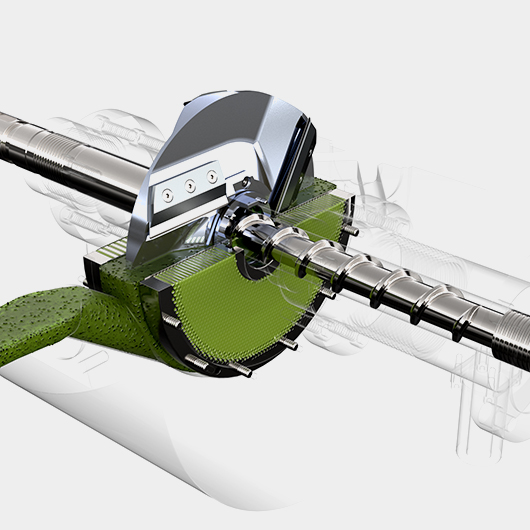

Here is how it works in 2 easy steps:

STEP 1

The plastic melt is conveyed into the filtration chamber, passing through 2 filters facing each other. The scraper disk between them rotates, removing the contamination deposited on the screens.

The plastic melt is conveyed into the filtration chamber, passing through 2 filters facing each other. The scraper disk between them rotates, removing the contamination deposited on the screens.

STEP 2

The contamination is channeled into the scraper’s center, and ejected by the discharge screw, which rotates independently, at a speed dependent on contamination.

The contamination is channeled into the scraper’s center, and ejected by the discharge screw, which rotates independently, at a speed dependent on contamination.

DUO scraper allows for a fast and controlled removal of contaminants, minimizing waste and increasing production volume.

Contact our team to learn more about DUO scraper