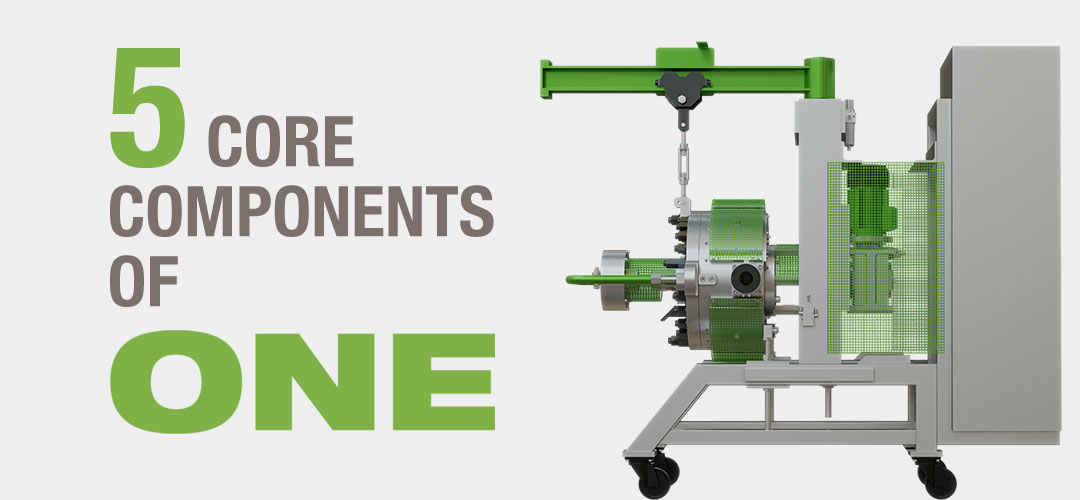

5 core components of ONE

Filtration is the most important step in plastic recycling. With this in mind, ONE’s filter chamber was engineered to meet the highest quality standards, enabling increased production, reliability, and longer screen utilization. Here are its 5 main components:

Main and secondary breakers

In the scraping operation mode, a thick steel breaker is coupled with a thinner, secondary breaker, enhancing passage and increasing the flow of plastic material.

Laser or punched screen

ONE works with interchangeable punched or laser mirco-perforated steel screens, tailored to the customer’s requirements, allowing filtrations from 120 to 2000 microns.

Spacer

The spacer is placed between the screen and the scraper, allowing them to maintain the correct distance and prevent screen damage.

Scraper

ONE’s scraper has 2 roles: cleans the surface of the screen from deposited impurities, and then collects and automatically expels the contaminants through the discharge valve.

Touch screen

ONE is equipped with a touch screen display, the graphic layout and reading parameters of which can be customized according to the customer’s desired production settings.