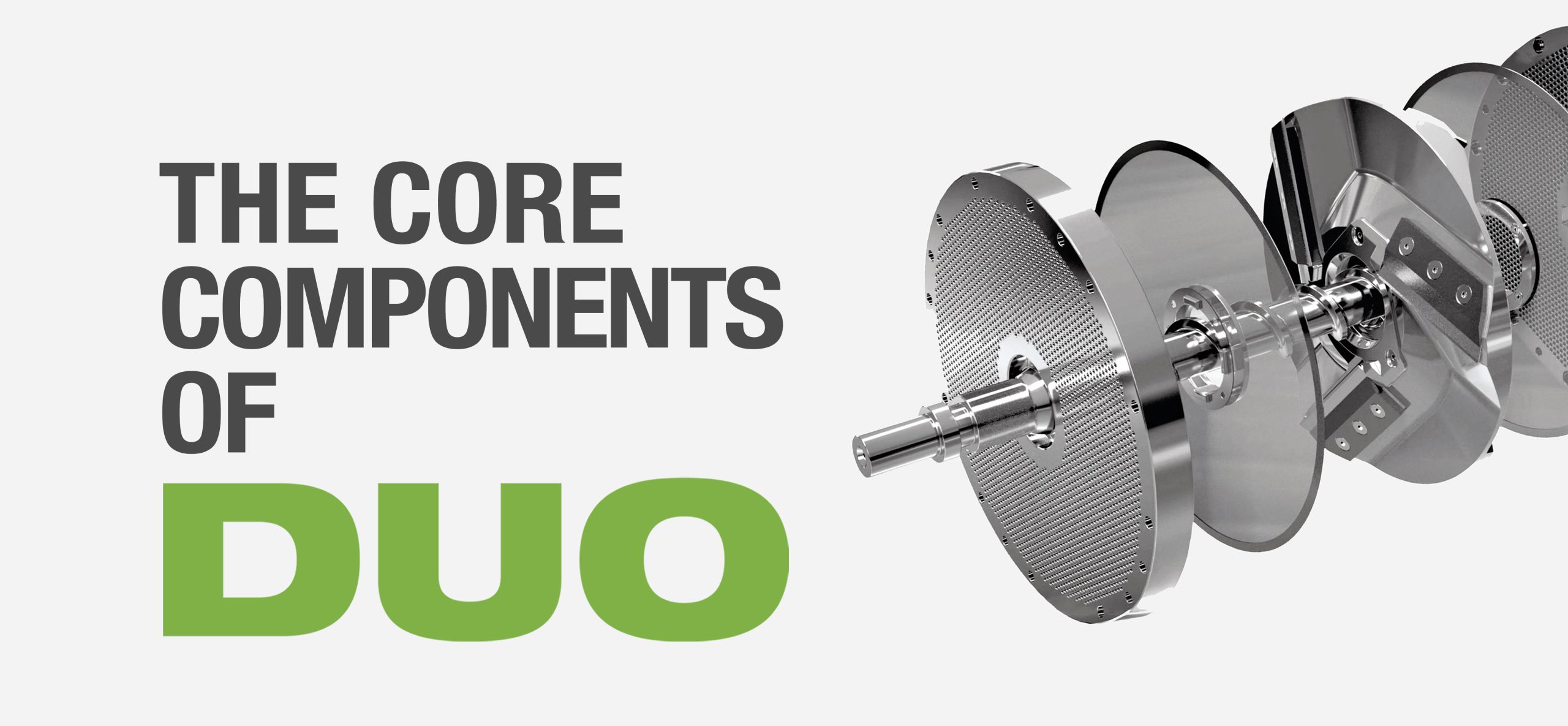

The core components of DUO

Here is a review of DUO’s core components, each playing a key role in ensuring efficient filtration and high productivity.

The DUO filter chamber is designed with an internal set of components that operate at a constant pressure, ensuring maximum productivity, system stability, and product quality. Its interchangeable components can be customized to support two operating modes – scraping and back-flushing – allowing it to filter both high and low contamination plastics.

Let’s review each component and explore its function.

DUO is designed to operate with two laser, punched, or metal mesh screens facing each other, positioned between two breakers. This larger filtering surface enables a smaller filtration chamber, higher production volume, and improved filtration efficiency for both high and low contamination plastics.

In scraping mode, used for high contamination, DUO operates with an independent scraper disc equipped with 6 blades that rotate between the two filters, continuously removing contaminants and channeling them to the center of the disc for efficient discharge.

In back-flushing mode, used for low contamination, DUO utilizes a cleaner placed between two metal meshes, which are positioned between two sets of breakers (supporting and protective). The cleaner gathers contamination settled on the mesh and channels it for discharge.

The center of the scraper disc or cleaner is connected to an independent discharge screw that efficiently expels contaminated material collected from the filter surfaces. Its adjustable speed allows DUO to process even highly contaminated materials, adapting to customer requirements.

To learn more about DUO, email Alessandro Sartori at alessandro.sartori@breakmachinery.com