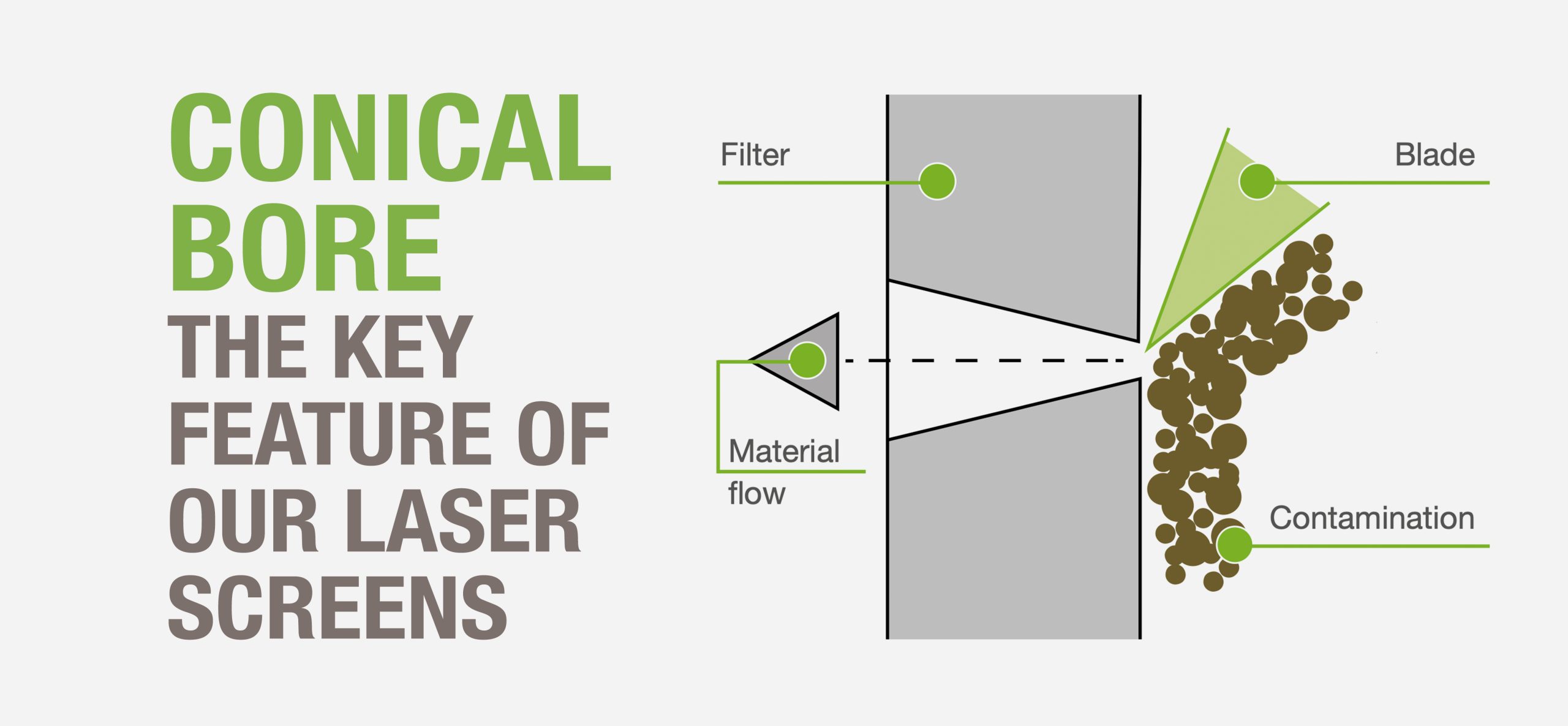

Conical bore: the key feature of our laser screens

Conical bore is a design detail of Break Machinery laser screens that extends the life of the filtering machine and enhances its overall performance.

At Break Machinery, we produce our laser screens in-house because we know how crucial they are to the filtration process. Their key feature? The conical bore – a small design detail that makes a big difference in the filtering machine’s performance and durability.

Optimized flow for better efficiency

Unlike traditional cylindrical openings, the conical bore is narrower at the bottom and wider at the top, allowing the molten plastic to flow faster and more efficiently through the screen. This geometry enables the filter to work at lower pressures, reducing energy consumption, minimizing stress on the machine, and improving overall extrusion stability.

Reduced friction for extended lifespan

The tapered bore shape also reduces friction and clogging, which helps extend the screen’s lifespan and improves its self-cleaning capabilities when combined with our DUO filtering system.

Lasting performance and cost savings

The result? A more durable, efficient, and cost-effective laser screen that extends the life of the filtering machine and enhances its overall performance, ensuring excellent results in every plastic recycling run.

To learn more about the design of Break Machinery laser screens, email Alessandro Sartori at alessandro.sartori@breakmachinery.com