Remove high contamination with DUO scraping mode

As plastic waste grows in scale and complexity, DUO scraping mode answers the rising demand for fast, precise filtration – even in the most contaminated streams.ASK US ABOUT DUO

With plastic waste increasing in both volume and environmental spread, our clients are consistently requesting advanced filtration systems capable of capturing even the smallest particles. DUO features a scraping mode that enables fast and precise removal of contaminants – even from highly polluted plastic material. Here is how it works:

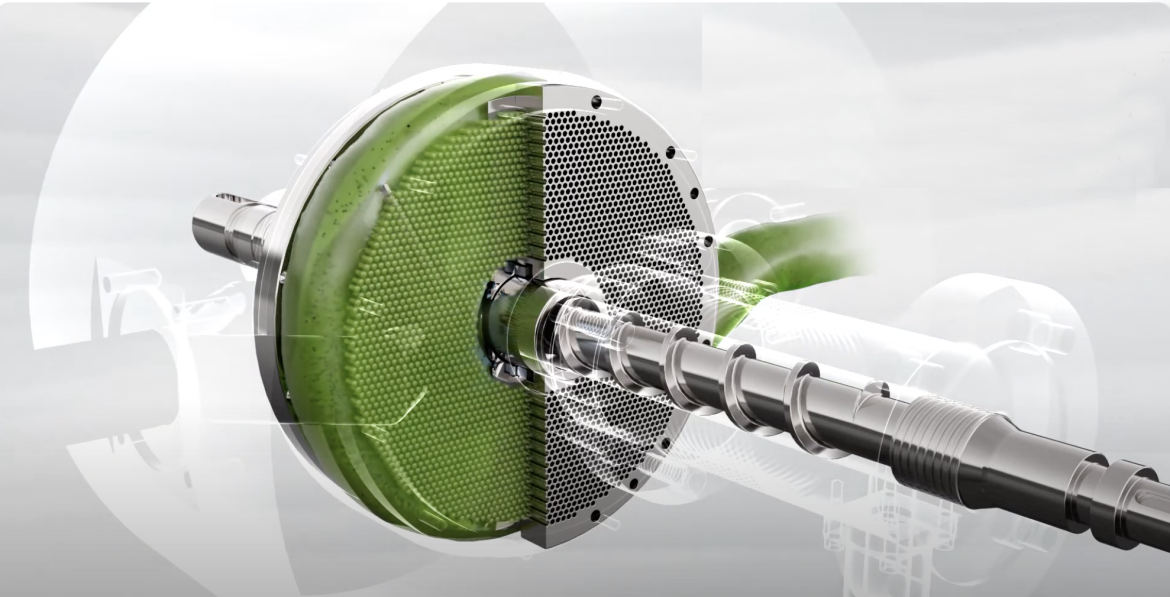

The melt passes through 2 screens

The melted plastic enters the filtration chamber, where it is pushed through 2 opposing laser or punched screens, placed in front of two supporting breakers.

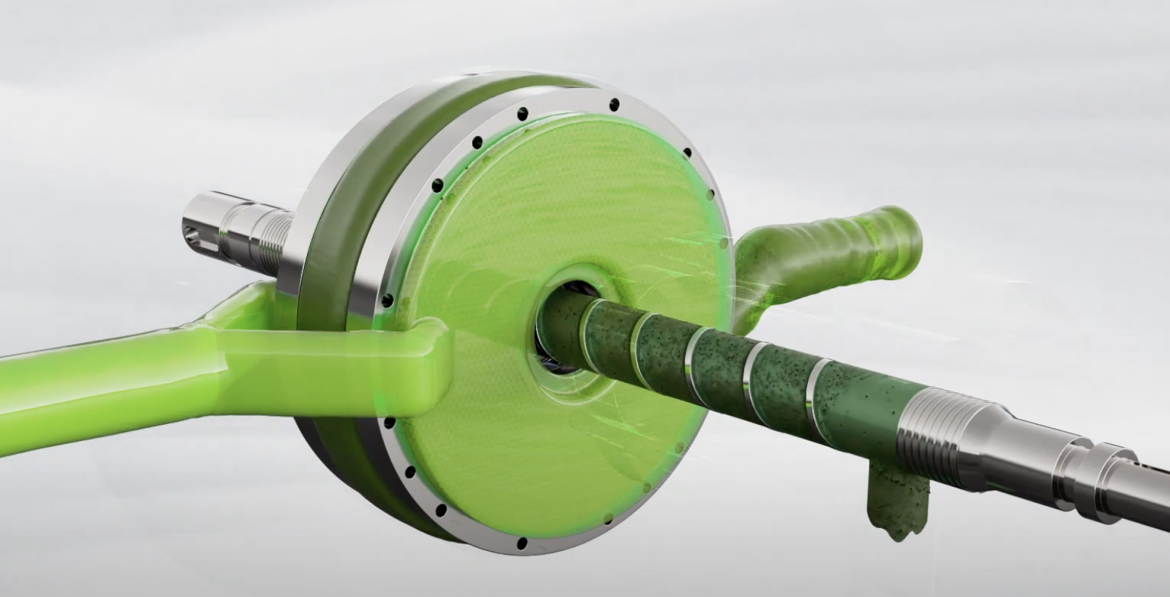

The scraper cleans both screens

At the core of the operation is a rotating scraper disc equipped with six blades that sweep contaminants off the screens and channel them into the disc’s center cavity.

Clean plastic is directed to the outlet

The clean plastic material is redirected to the outlet channel, ready for the next processing stage.

The discharge screw expels impurities

The scraper disk cavity is directly connected to an independent discharge screw, which automatically expels the impurities.

To learn more about DUO, email Alessandro Sartori at alessandro.sartori@breakmachinery.com