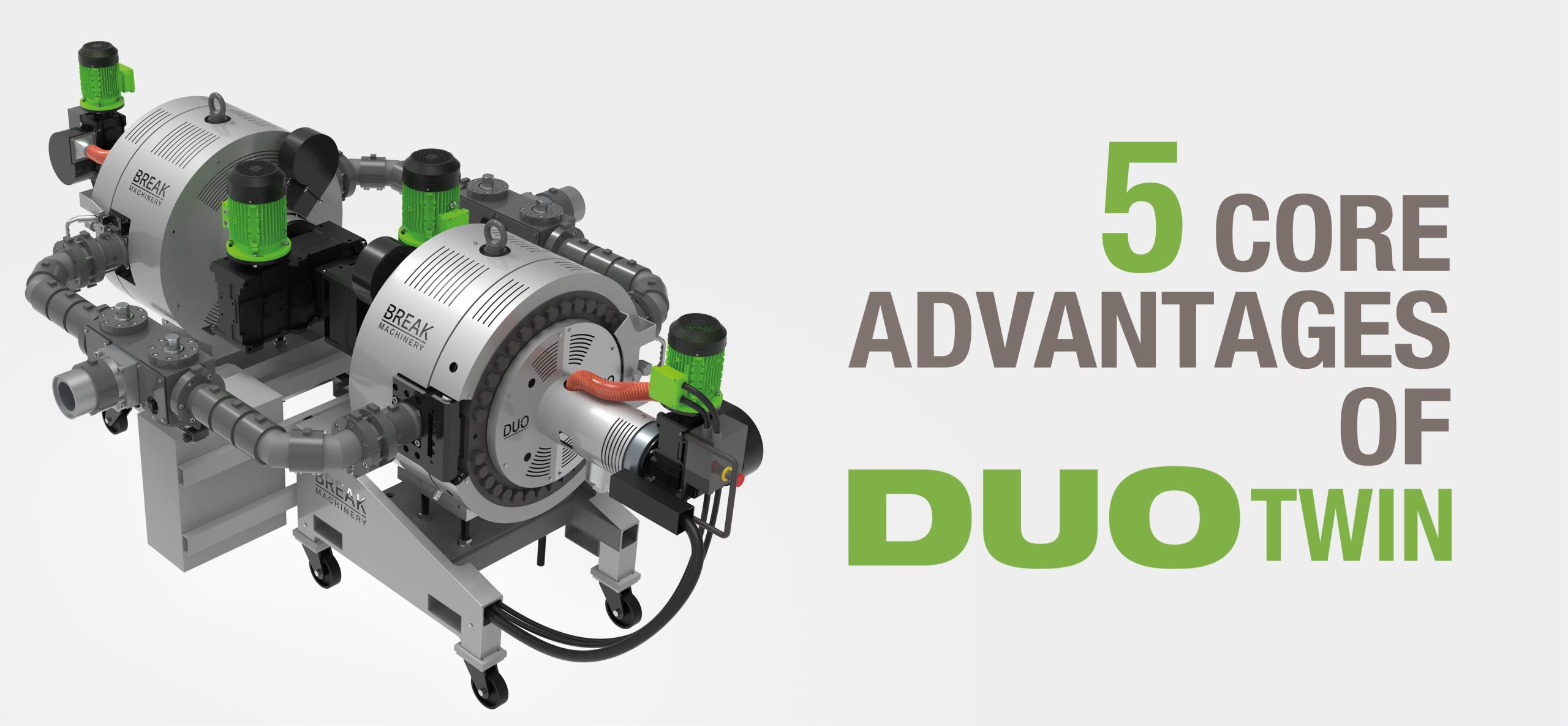

5 core advantages of DUO Twin

DUO Twin is our new configuration, combining two identical DUO machines working seamlessly together.

Below are its five key advantages, each aimed at optimizing production performance and efficiency.

In our commitment to enhancing your production efficiency, we developed DUO Twin – two identical DUO machines working seamlessly together. Building on the strengths of an individual DUO machine, DUO Twin shares its benefits while introducing new, unique advantages. Discover the 5 key ways DUO Twin improves your recycling line and maximizes production output.

Double output

DUO Twin consists of two double-screen, self-cleaning systems running in parallel at constant pressure. Each DUO machine ensures high product quality with minimal waste, and together, they double the production output.

Seamless screen change

When a screen change is required, the flow in one DUO Twin branch is stopped while the other continues production. The process is then repeated in the second machine, ensuring minimal disruption to the production flow.

Continuous production

The ability to perform screen changes or maintenance without stopping the filtration process ensures a continuous material flow. This keeps production running smoothly without interruptions, improving overall efficiency.

Enhanced customization

DUO adapts to your recycling line setup with adjustable height, chamber lid openings, and switchboard positioning. Additionally, DUO Twin provides interchangeable opening/closing valves and customizable material inlet/outlet positions to meet your specific requirements.

Versatility

Like DUO, Twin can be installed on both regeneration and extrusion lines, capable of filtering both lightly contaminated post-industrial material and heavily contaminated post-consumer waste. With expanded customization options, it can also be adapted to a broader range of production setups, further enhancing its versatility.

To learn more about DUO Twin, email Alessandro Sartori at alessandro.sartori@breakmachinery.com