ONE self-cleaning filter system

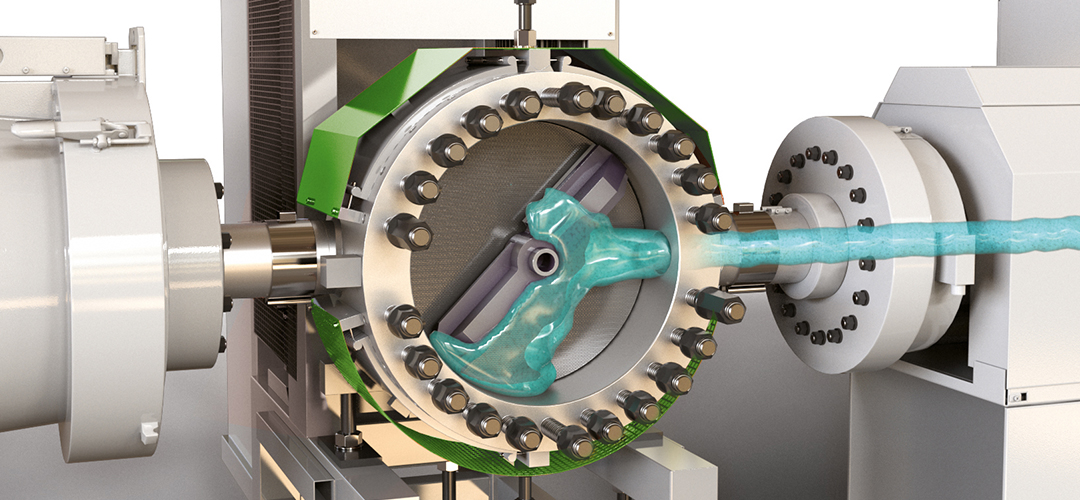

ONE is a screen changer with an automatic filter surface cleaning system that saves a lot of time during production. It is suitable for manufacturing recycling granules, polymerization granules, masterbatch, and compound granules. Here is how it works.

The contaminated plastic is pushed from the extruder into the ONE filtration chamber.

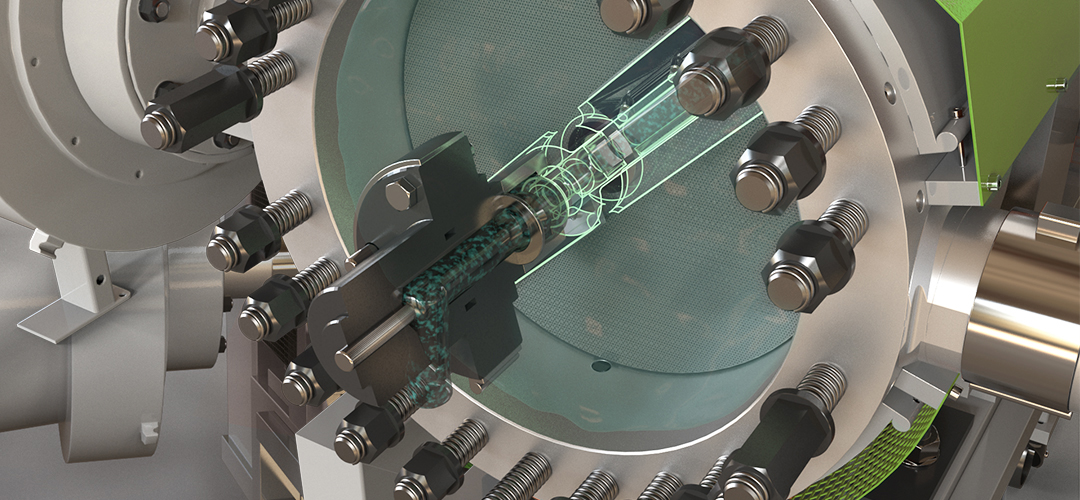

The plastic is filtered through a perforated steel plate. The customer can choose between punched or laser-perforated filters.

The cleaned plastic leaves ONE filtration chamber and passes to the next processing steps.

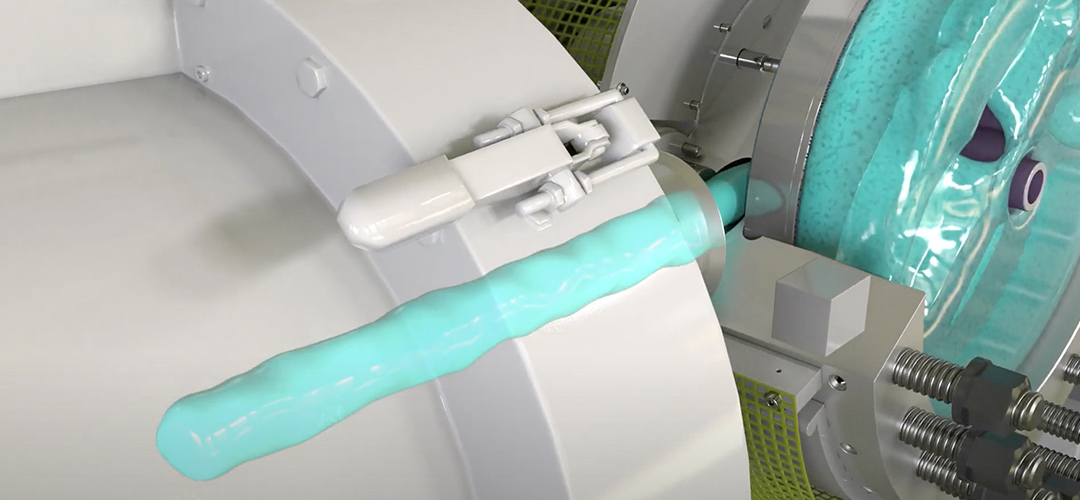

The scraper cleans the surface of the filter sheet and collects the impurities by conveying them to the valve, which discharges them outside.

For more email Alessandro Sartori, our Chief Engineering Officer at alessandro.sartori@breakmachinery.com